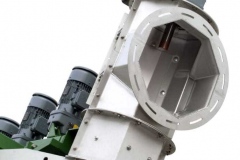

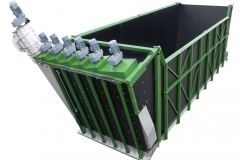

The BioFeeder is a unique and innovative feeding system, which transports long-fiber and unevenly structured materials such as straw, manure or catch crops into the conveyor without clogging or bridging due to the intelligent interaction of the conveyor motors. An OPTIFEED control system reacts to different structures and thus allows the problem-free use of biogenic residues and waste materials.

Perfect mixing of components

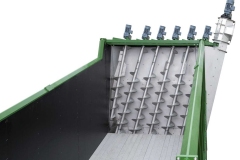

Due to the well thought-out arrangement of the screws, a mixing effect is achieved in the immediate removal area of the storage container. In this way, the subsequent fermenter, defibrator or pump technology is continuously fed with the different substrates. All the substrate carrying parts of the BioFeeder and the other conveying elements or screw conveyors are made of corrosion resistant stainless steel as standard.

Durability of the biogas feeding system

The walls of the BioFeeder are batten with phenolic resin-coated multilayer composite panels or optionally with polyethylene or stainless steel. Due to the feeding concept, the BioFeeder moves the material to the dosing unit with a minimum energy consumption. The possibility to reverse the feed direction of the BioFeeder and to control it in the opposite direction is what makes the solution unique.

Individual models

This feeding technique is offered with a capacity of 12 to 240 m³. Of course, the feeding technology is individually adapted to each biogas plant.